|

|

Sitemap |

|

FAQ |

Welcome to Anber Powder Coating Co., Ltd's website! |

|

| |

Powder coating lines Powder coating lines

Components of powder coating line Components of powder coating line |

|

Coil painting line

Color painted coil production line  Continuous color painting line  Continuous metal coil painting line  Curing furnace for aluminium painted coil  Curing oven for metal coil  Painting machine for steel coil  Re-coiler for painted metal coil  Coated steel coil receiving machine  Collecting device for painted coil  Color coated aluminium coil  Finished aluminium coil from coil painting line

Technical parameters Technical parameters

1. Products need to be painted: Aluminium coil or steel coil

2. Coil weight: Max 400kg

3. Coil thickness: 0.22-0.45mm

4. Outer diameter of coils: 800mm

5. Inner diameter of coils: 400mm

6. Painting speed: 5-20m/min

7. Position error of finished coils: ±2mm

8. Heating source: natural gas (Other choices are available: electricity, oil or coal)

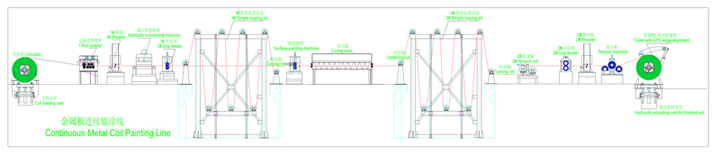

Layout Plan for Metal Coil Painting Line Layout Plan for Metal Coil Painting Line

Process flow Process flow

Coil loading cart → hydraulic expanding drum uncoiler → roll leveler → First shearing machine → hydraulic conecting machine → first grip feeder → first turning roll → First looping pit → Second turning roll → surface painting → paint curing → centring roll → second looping pit → turning roll → tension roll → second grip feeder → second shearing machine → tension machine → hydraulic coiler with EPC edge alignment → hydraulic unloading cart → stocking

Related keywords Related keywords

Aluminium coil painting line, steel coil painting line, metal coil painting line, color painting line for aluminium coil, color painting line for steel coil, continuous painting line, coil painting line, coil coating line, color coating line for aluminium coil, color coating line for steel coil, metal coil continuous color painting line, color coated coil production line, color painted coil production line.

|

| |

|