|

|

Sitemap |

|

FAQ |

Welcome to Anber Powder Coating Co., Ltd's website! |

|

| |

Powder coating lines Powder coating lines

Components of powder coating line Components of powder coating line |

|

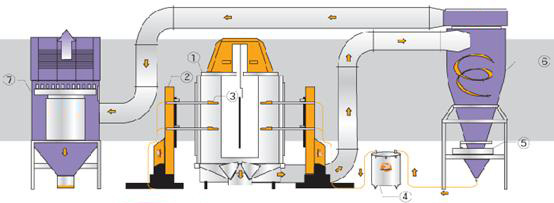

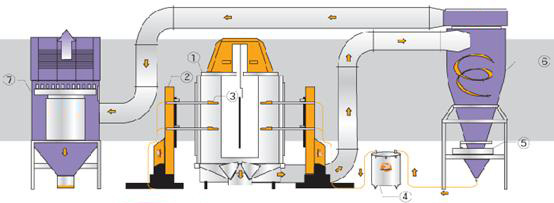

Overspray powder recycling unit

Stainless steel multi cyclone installed on stainless steel powder booth  Multi-cyclone for powder recovery  Stainless steel multi cyclone overspray powder recycling system  Multicyclone overspray powder collector  Small cyclone powder recycling unit  Overspray powder recovery system with multi cyclone separator  Multi cyclone recycling unit for waste powder  Small-diameter cyclone powder separator .jpg) 2 stage overspray powder recycling unit (stainless steel twin cyclone and filter element)  Powder collecting outlet of stainless steel twin cyclone

How overspray powder been recovered?

1.Powder spray booth

2.Reciprocator for auto spray gun (gun mover)

3.Auto spray gun

4.Powder feed hopper

5.Powder sieve machine

6.Cyclone recovery

7.Cartridge filter recovery

Cyclone collectors for overspray powder Cyclone collectors for overspray powder

The powder that is not deposited onto the objects in the spray booth (overspray) is not wasted. It is recovered and re-used. This recovery process is driven by an exhaust air ventilator that provides an airstream powerful enough to flow through the related extractor equipment such as a cyclone and filters. The input to the cyclone is connected to the booth while the output is connected to a suitable exhaust fan. The overspray powder arrives at the cyclone inlet at a velocity of about 20 metres per second. On entering the cyclone chamber tangentially the air/powder mixture is given a rotary motion which creates a centrifugal force on the particles. The larger and heavier particles tend to be ejected to the outside walls of the chamber and fall to the bottom where they are collected. The lighter fractions will stay suspended in the air stream which on reaching the bottom is deflected by a conical tail air/powder mix into a rising spiral which is then carried through the central stack to a filter collector. For a standard powder the recovery efficiency can be as high as 90%. For lines that have a high percentage of particles in the recovered powder the recovery efficiency will be reduced (as low as 75%). Inevitably therefore a cartridge filter is used in conjunction with a cyclone solely to prevent discharge of the fine powder to the atmosphere. An additional advantage of cyclone recovery, with particular reference to colour change, is that due to frictional contact of powder particles, one with another and ‘bounce-back’, little or no adherence of powder particles occurs on the cyclone wall. This means that in many cases only the powder collection hopper need be thoroughly cleaned between colour changes. |

| |

|