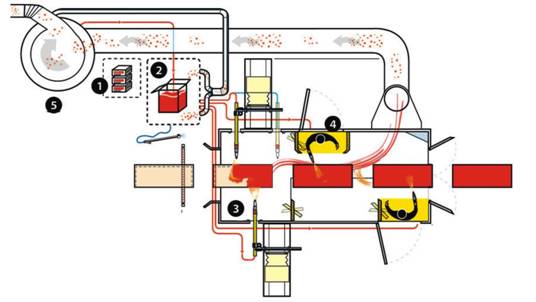

Powder painting booth with multi-cyclone overspray powder recycling unit and auto reciprocator

Complete stainless steel powder booth for industrial powder coating line

Manual powder booth wuth twin cyclon overspray powder recycling unit

Powder painting room with overhead conveyor

Powder spraying room with assistance stand

Stainless steel powder booth with auto gun mover

Stainless steel powder room with conveyorized system

Powder sptay booth for manual powder coating line

Stainless steel powder spray booth

Top channel for workpiece passage

PE spray booth features quick color change

Manual powder booth for new investor with small budget

Opening for manual spray gun

PE powder booth for fast color change

End view of powder sptay room

Basic frame of powder painting booth

End view of powder application booth

Assistance floor stand for worker manually spray on long workpieces

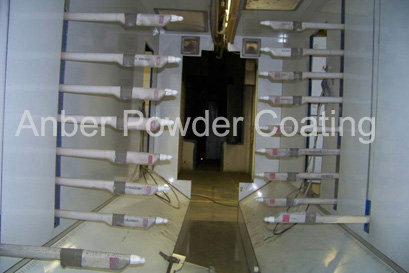

Inner gun arrangment for large powder painting room

Inner view of powder painting room

Inner stucture of metal powder spray booth

Auto spry guns working on the conveying aluminium profiles

.jpg)

Auto and manual spray guns working (inner of powder booth)

Powder coated objects coming out from spray booth

Stainless steel manual powder painting room

Cleaning of plastical powder for quick color change

.jpg)

Reciprocator for auto powder spray gun (gun mover)