.jpg)

Automatic powder application gun (imported from Nordson)

.jpg)

Automatic powder coating spray gun in working (imported from Nordson)

Gema automatic powder coating gun

Auto Gema powder painting gun with spare part kit

.jpg)

Automatic powder coating gun (Made-in-China)

.jpg)

Automatic electrostatic powder coating spray gun (Made in China)

.jpg)

Automatic electrostatic powder painting gun (imported from GEMA)

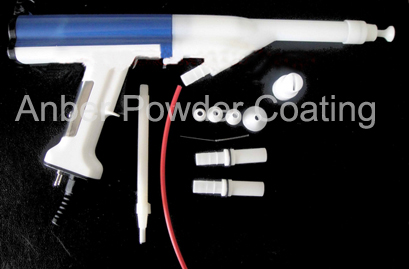

GEMA manual electrostatic powder painting gun

Manual electrostatic powder spray gun with replacement kit

.jpg)

Manual powder gun (Gema - OptiSelect series)

Powder application equipment from Gema

Cheap chinese brand manual powder gun

.jpg)

Manual electrostatic powder spray gun (made in China)

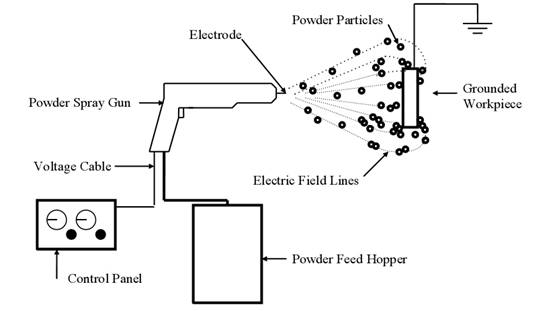

Electrostatic powder coating application gun

Manual powder coating gun with spare parts

Auto reciprocator for the movement of auto powder spray gun

Gun mover for the auto powder application

.jpg)

Manual powder painting center (powder gun, feed hopper with digital controller)

Electrostatic manual powder spray application equipment

Electrostatic powder coating machine

Digital display electrostatic powder coating equipment

Electrostatic powder spraying equipment

Intelligent powder coating machine

Manual electrostaticl powder coating system

Manual powder coating gun system

Electrostatic powder coating spray gun machine

Manual powder spraying center

Pulse powder coating system