Powder coating lines Powder coating lines

Components of powder coating line Components of powder coating line |

|

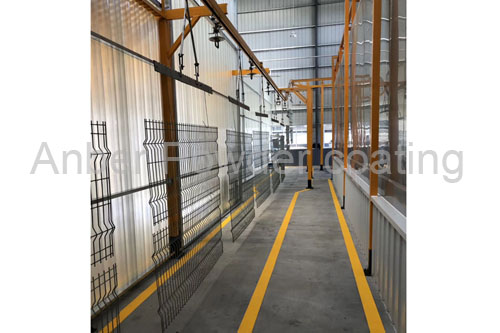

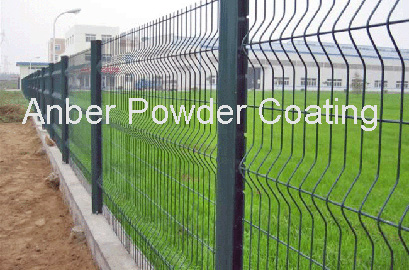

Wire welded mesh powder coating line

Fence sheet powder coating line  Iron wire mesh powder coating line  Twin wire mesh powder coating line  Paladin fence powder painting line  Iron mesh sheet powder coating line  Sports fence powder painting line  Iron mesh sheet powder coating line  Loading area of mesh fence powder coating line  Unloading area of wire mesh powder coating line  Wire mesh panel powder coating line  Welded wire mesh powder coating line  Panel mesh fence powder coating line  Mesh panel powder coating line  Fluidized bed for powder application on wire fence sheet  Wire mesh fence powder coating line  Powder coating line for mesh railing  High security wire mesh fence powder coating line  Powder coating line for paladin fence  Decorative fence powder coating line  Decorative fence powder painting line

Design basis for welded wire mesh powder coating line Design basis for welded wire mesh powder coating line

1. Name of workpiece: Wire welded mesh

2. Max hanging size on each hanger: L3000mm×W100mm×H1800mm

3. Loading capacity on hanging hook: ≤50kg (2-4pcs per hook, depends different hole size)

4. Suggested interval between 2 hangers: 500mm

5. Conveying speed: 1.3m/min (Adjustable control)

6. Output: 45-90pcs per hour

7. Spraying method: 4 auto spray guns (match on 2 reciprocators) & 2 manual spray guns

8. Heating source: natural gas (Other choices are available: electricity, oil or coal)

9. Pretreatment system: Immersion tank type

10. Required plant size: L52m×W24m×H6.5mm

Design description of mesh fence powder coating line Design description of mesh fence powder coating line

1. According to the shape of welded wire mesh, we design the pretreatment to be economical immersion tank type with 6 stage processings.

2. After chemical cleaning, he pre-treated workpieces will be conveyed to drying furnace for water removal on their surface. The drying furnace is designed being tank type to match with immersion pretreatment tanks, and with a top-door design for easy access of pre-treated workpieces.

3. After drying, the workpieces are ready for powder particle adhesion. Please manually feed them on auto powder painting line. For a better painting result, the spray booth, waster powder recycling system, reciprocator adopts advanced equipments in China through our careful selection. And the spraying guns, both auto and manual are imported from foreign famous company for a longer service life. Then these workpieces will be sent to gas-fired furnace tunnel to let powder melt into a smooth coating.

Process flow for mesh sheet powder coating line Process flow for mesh sheet powder coating line

1. Feed your welded wire mesh on this automatic powder coating line

2. Pre-degreasing stage (50-65 Celsuis for 1 min)

3. Degreasing stage (50-65 Celsuis for 2 mins)

4. Rinsing stage (Room temperature for 1-2 mins)

5. Surface conditioning stage (Room temperature for 1 min)

6. Phosphating stage (35-45 Celsuis for 3 mins)

7. Rinsing stage (Room temperature for 1-2 mins)

8. Drying off oven to remove surface moisture (100-120 Celsuis for 10 mins)

9. Manually transfer the pre-treated objects to powder coating line

10. Powder application with spray guns

11. Powder curing (180-200 Celsuis for 20 mins)

12. Finished product discharging

If above parameters cannot meet with your strict coating need, please contact us for more detail. We can make some adjustments or even improvements to suit your actual production conditions.

Related keywords for fence sheet powder coating line Related keywords for fence sheet powder coating line

Welded wire mesh powder coating line, Welded wire mesh powder painting line, Welded wire mesh powder spraying line, Semi automatic powder coating line for welded wire mesh, Mesh fence powder coating line, Fence sheet powder coating line, Panel mesh powder coating line, Mesh panel powder coating line, Mesh sheet powder coating line.

|