|

|

Sitemap |

|

FAQ |

Welcome to Anber Powder Coating Co., Ltd's website! |

|

| |

Powder coating lines Powder coating lines

Components of powder coating line Components of powder coating line |

|

If you are a new investor for powder coating line with a small budget, please click here for our economical immersion tank type pretreatment system.

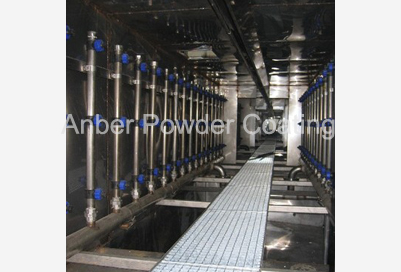

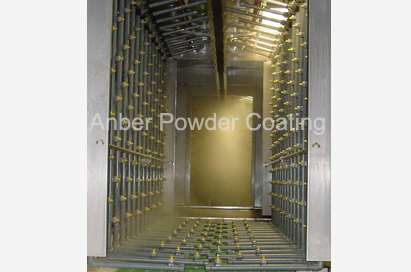

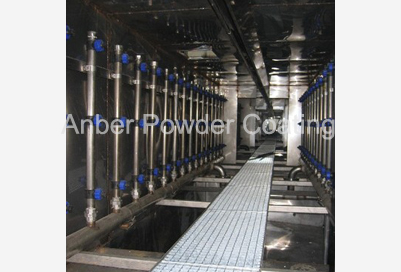

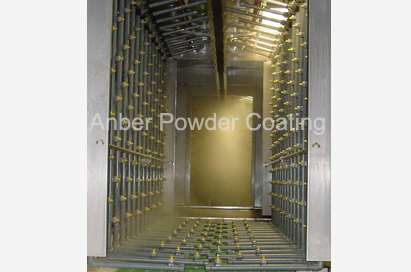

In-line spray washer system  Vertical spray pretreatment system  Stainless steel vertical spray pretreatment shower  Bottom chemical pump for spray washer  Bottom water recycling tank  Cleaning solution for high auto powder coating line  Stainless steel aqueous spray washer system  Adjustable spraying direction nozzles for vertical chemical cleaning system  Inner pipeline & nozzle arrangment for pretreatment shower  Inner spray nozzles for washer tunnel  Stainless steel pipeline with PP spray nozzles  Chemical cleaning solution with density internal design  Vertical wash tunnel for powder coating line

Pretreatment system: preparation for powder adhesion Pretreatment system: preparation for powder adhesion

Proper surface preparation is the single most important aspect of a powder finishing system should you wish to maximise powder performance. The procedure required to obtain a suitably prepared surface depend heavily on the type of substrate but in most cases the following steps are required:

● Cleaning

The cleaner will depend on both the substrate and the soils to be removed e.g. synthetic draw lubricants are much easier to remove than a buffing or polishing compound. Metal oxides (rust) need to be removed at this point as they will act as a barrier to powder coating film adhesion. This is normally achieved by using an acid deruster

● Conversion Coating

Conversion coatings are materials and processes that impart corrosion resistance better adhesion properties to a metal substrate. The type of conversion coating depends heavily on the nature of the substrate as well as the desired properties of the coating.

Aluminium - The aluminium surface is treated with a chromate conversion coating to produce a surface layer that comprises of both aluminium and chrome oxides. This is a smooth uniform surface that is chemically inert and allows good adhesion of the organic coating.

Iron & Steel - Zinc Phosphate or Iron Phosphate is used depending on the mechanical properties and corrosion resistance required from the finished part.

● Passivation

A passivator (seal rinse) is applied over a zinc or iron phosphate to increase the corrosion resistance of the coating and to improve adhesion of paint and organic finishes. Passivation is important if components are going to be stored or transported between chemical treatment and powder coating.

● Rinsing

The work pieces are rinsed between stages to prevent cross contamination of process solutions and to reduce chemical consumption. The final rinse prior to drying is to remove any unreacted chemical or salts that could adversely affect adhesion.

Features of vertical spray shower pretreatment system Features of vertical spray shower pretreatment system

● Advantages of vertical spray shower pretreatment system

1.Can be easily automated

2.Plant can be built in line with application of powder coating

3.Better cleaning

4.Lower chemical cost

5.Increased throughput

6.Less energy for heating

● Disadvantages of vertical spray shower pretreatment system

1.Higher capital and maintenance cost

2.More difficult to protect deep recesses or difficult shapes

3.Small items pre-treated less efficiently

4.Troubleshooting with more expertise

Typical Pretreatment Example: only for your reference Typical Pretreatment Example: only for your reference

● For aluminium objects

1.Pickling: 3-5 mins (Room temp.)

2.1st Rinsing: 1-2 mins (Room temp.)

3.2nd Rinsing: 1-2 mins (Room temp.)

4.Chromizing: 2-5 mins (25-35℃)

5.3rd Rinsing: 1-2 mins (Room temp.)

6.Final rinsing: 1-2 mins (Room temp.)

● For steel & iron objects

1.Degreasing: 2 mins (50-65℃)

2.1st Rinsing: 1 min (Room temp.)

3.2nd Rinsing: 1 min (Room temp.)

4.Surface conditioning: 1 min (Room temp.)

5.Phosphating: 2.5 mins (35-45℃)

6.Final DI Rinsing: 0.5 min (Room temp.)

Note: The above pretreatment examples are only for reference. We advise consulting your chemical supplier to obtain the correct conditions to meet the required specifications. We stress that all chemical pretreatment processes must be maintained to the chemical suppliers specification to ensure continuous quality powder coating.

|

| |

|